From Vision to Practice

Climate Action - YFY’s Superiority in Carbon Sink

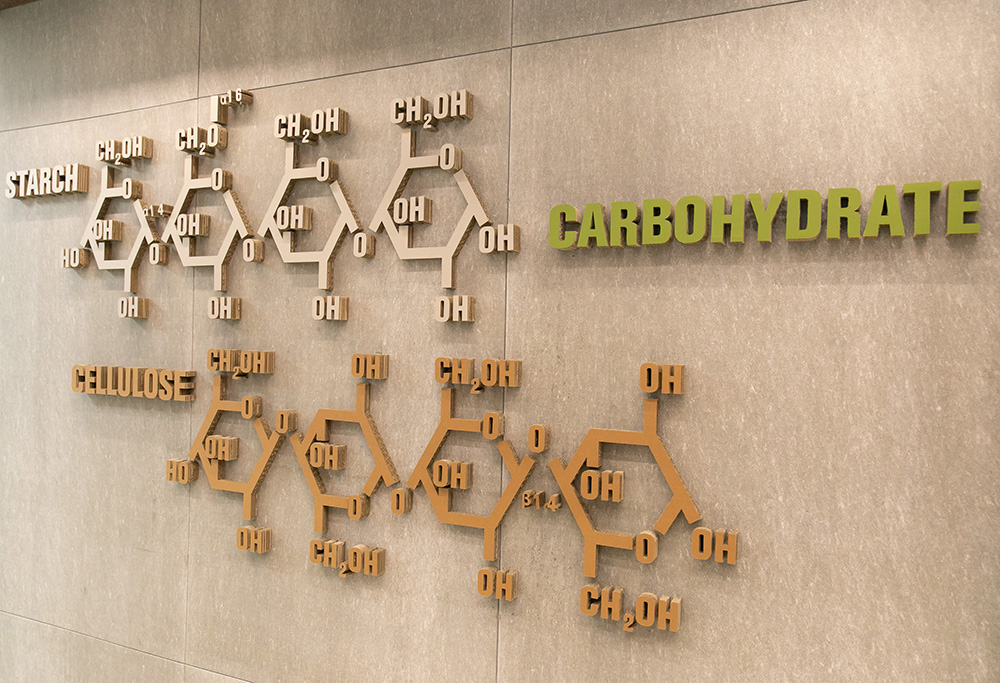

Carbon fixation of fiber

During photosynthesis, CO₂ is converted into plant cellulose and stored as starch in the roots. Consequently,CO₂ is fixed in cellulose and starch, which are key raw materials for papermaking. Paper undergoes continuous recycling throughout its production and use. The carbon initially stored in tree fibers remains sequestered throughout the paper's life cycle. The longer the paper is used, the longer the carbon stays out of the atmosphere, and recycling paper can further prolong this sequestration. Eventually, the CO₂ is released back into the atmosphere, maintaining a cycle of carbon storage in paper.

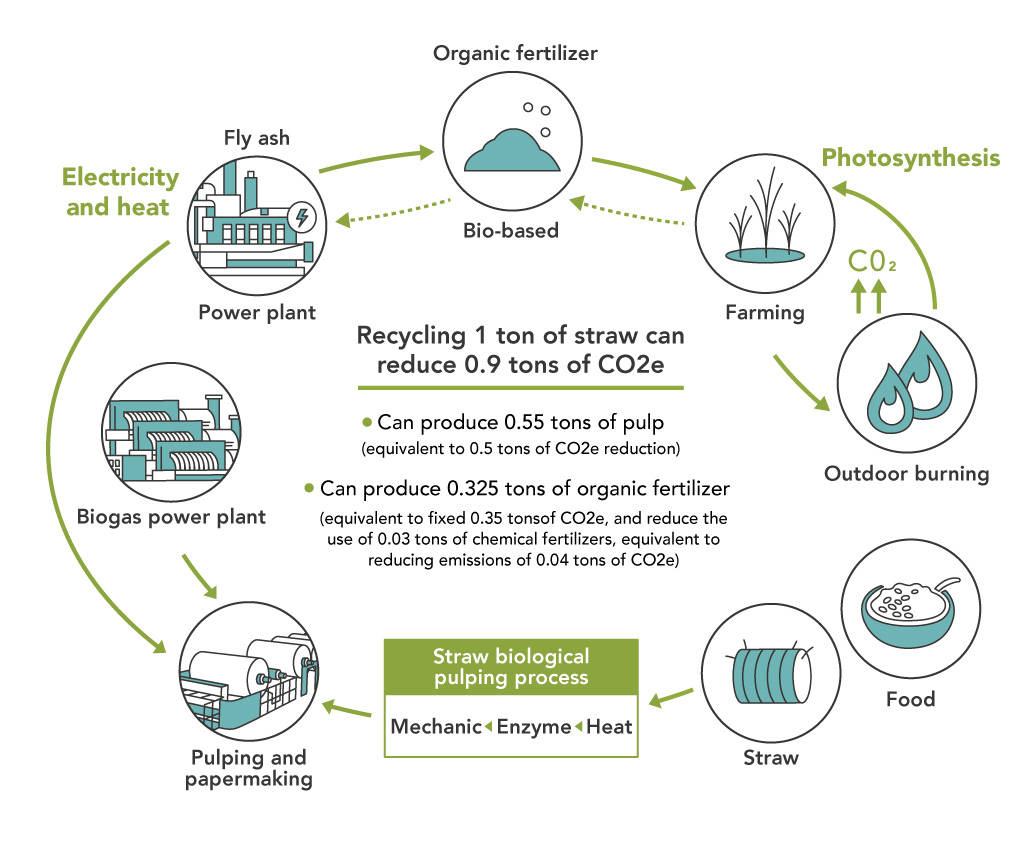

Carbon reduction of alternative fuels

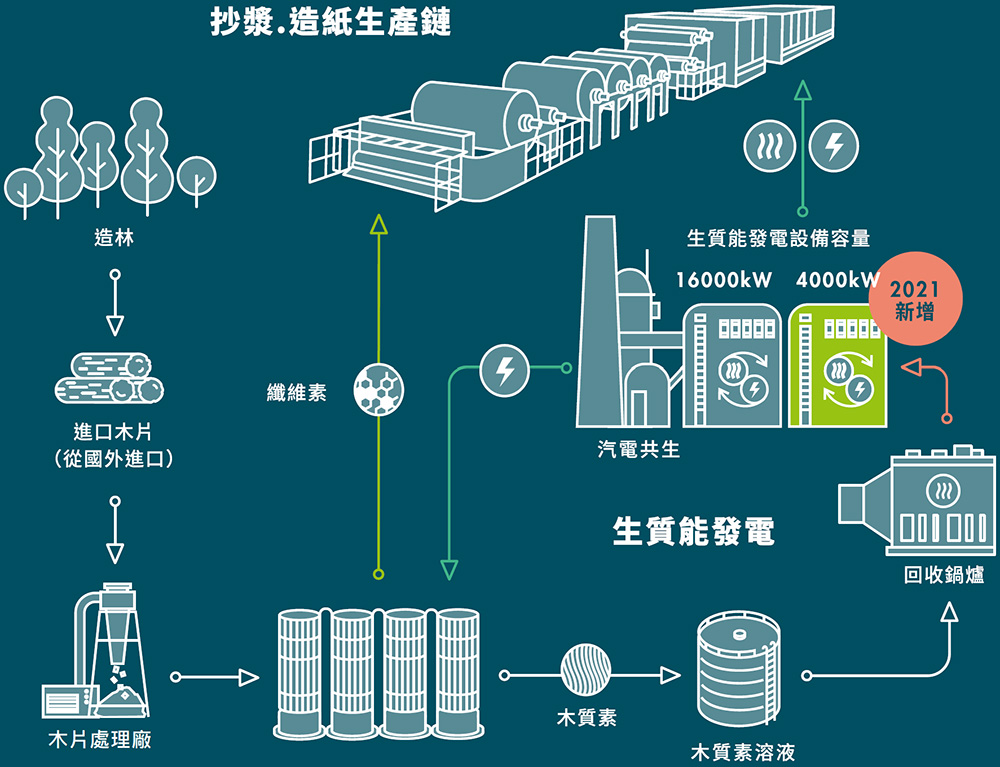

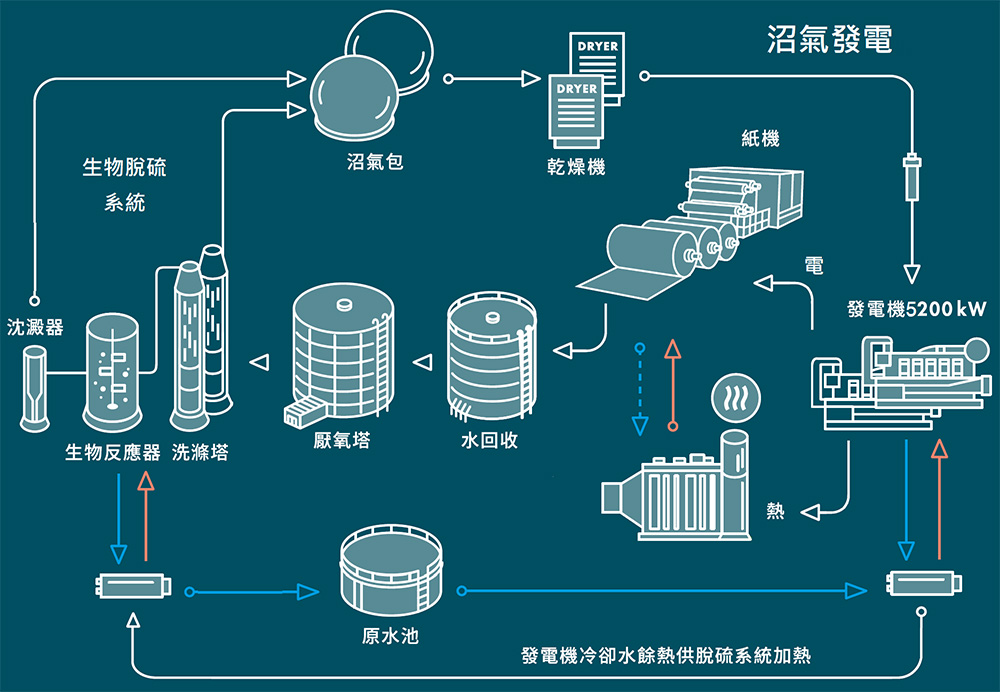

YFY is dedicated to the full cycle of energy resources, focusing on the development of large-scale alternative fuels and renewable energy. We "coal replacement" initiative aims to substitute high-carbon fossil fuels with alternatives such as lignin power generation, biogas power generation, and SRF steam-power symbiosis systems. This initiative is a key part of YFY's carbon reduction efforts. In 2023, Taiwan's factories reduced Scope 1 emissions by 9.8% compared to 2018 by using alternative fuels and biomass energy. Additionally, due to the continued expansion of biomass alternative fuels, Taiwan's biomass emissions in 2023 totaled 699,000 tCO₂e, marking a 3.9% increase from the previous year.

Carbon Sink of Forest

Carbon fixation in forests is a process of capturing and storing atmospheric carbon dioxide through photosynthesis, which has a positive impact on climate change. The carbon fixation of YFY Chung Hwa Pulp’s planting area on both sides of the Taiwan Strait covers more than 30,000 hectares, with 29,463 hectares on the mainland and approximately 1,000 hectares in Taiwan. This has led to the development of a distinctive carbon sequestration industry chain, spanning from afforestation to papermaking.

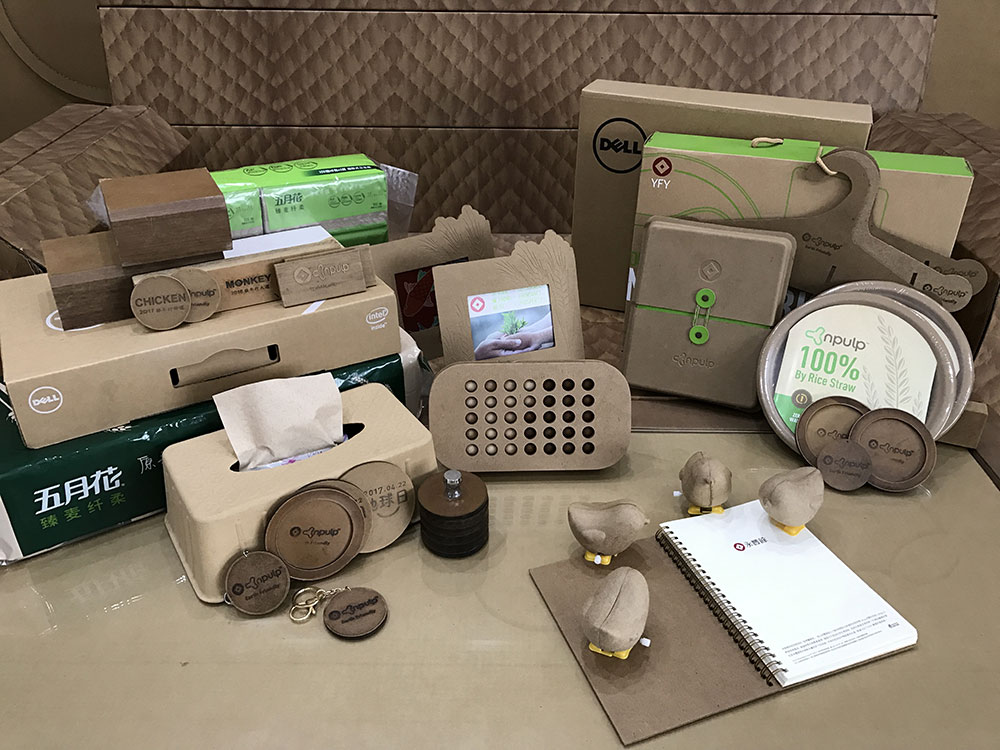

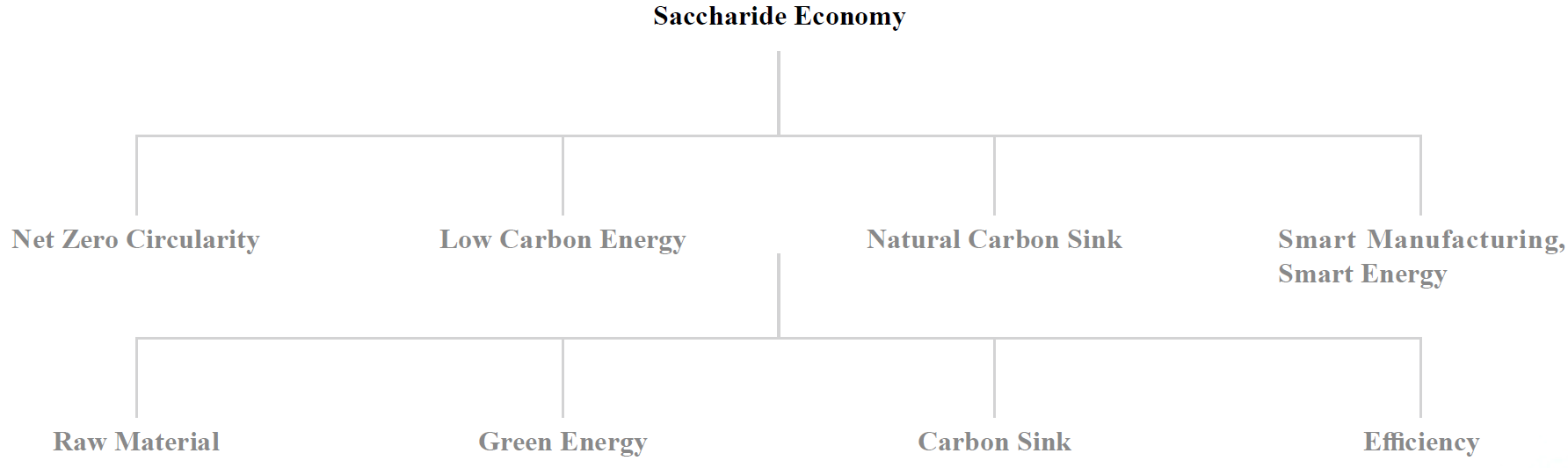

Unique model of circular economy

- with strong local signi cance in Taiwan.

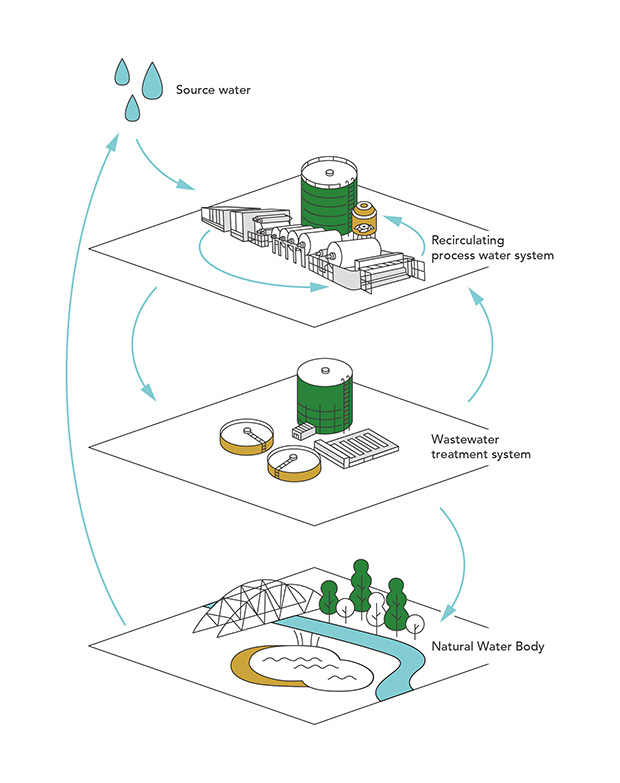

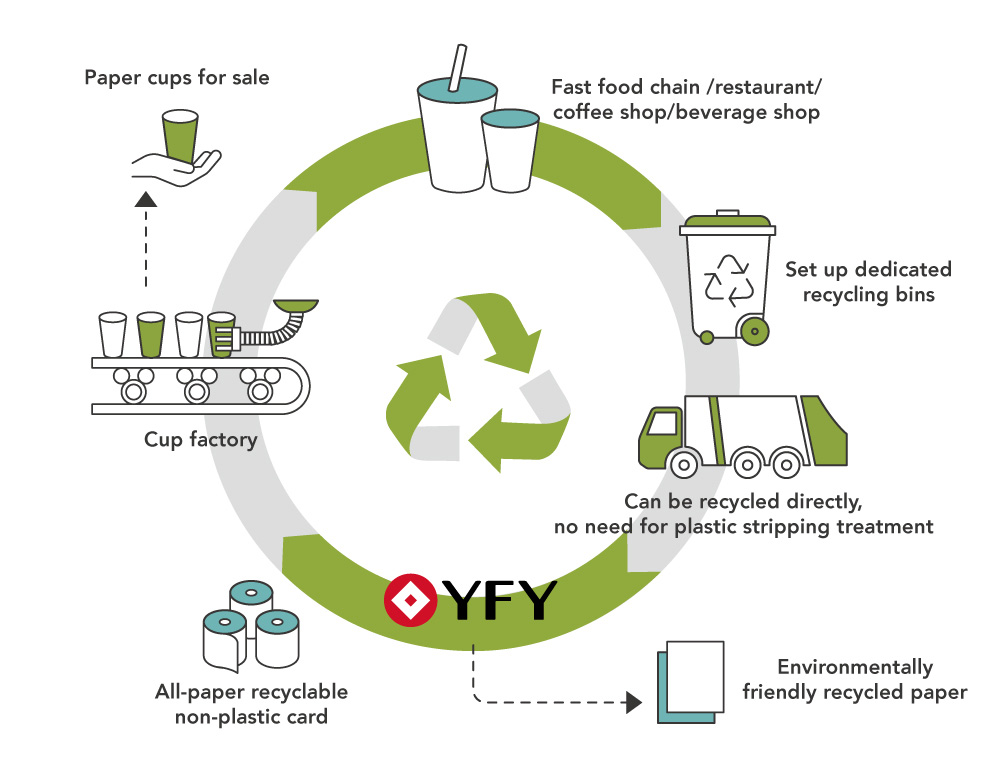

Since the generation change, YFY follows the goal of global sustainable development and focuses on innovation as a reaction. By linking the features of responsible production, water purification and forest protection, sustainable energy, ecological conservation, and climate action, the company completes the five cycles of renewable energy cycle, hydrologic cycle, agricultural cycle, paper cycle, and carbon cycle throughout decades of development.

This closed circulatory system is intertwined, and it is by no means an overnight success.

It is the result of generations of people who have worked hard to practice sustainable values.